All of HART’s Industrial Unions can be configured for high temperature or steam applications upon request. HART offers both High-Temp Steam Rated EPDM (Parker E0962 Compound) and Spiralwound Graphite gaskets to provide Class 3000 service and Class 6000 service in high temperature or harsh steam environments. Operational considerations like temperature, media, and pressure will determine the appropriate selection of high-temperature / steam union.

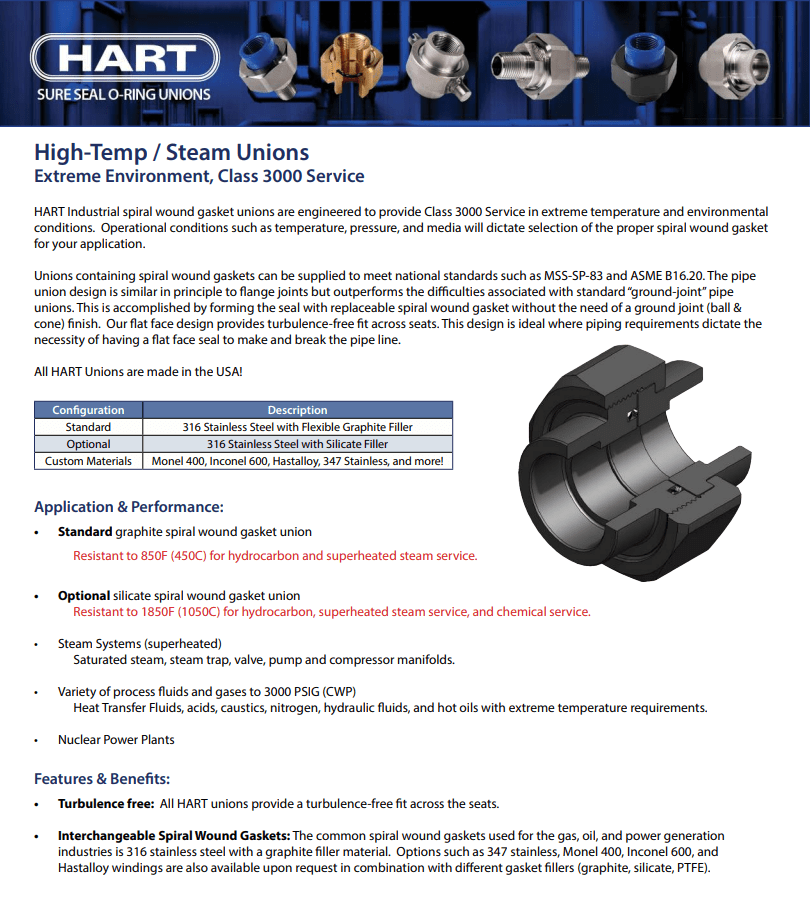

High-Temp / Steam Unions – Extreme Environment, Class 3000 Service

Parker E0962 Compound EPDM for Steam and high-temperature applications up to 550*F

Standard 316SS/Graphite Spiralwound Gasket

Resistant to 850*F for hydrocarbon and superheated steam service!

Higher Temperature custom options available!

| Standard | 316 Stainless Steel with Flexible Graphite Filler |

| Optional | 316 Stainless Steel with Silicate Filler |

| Custom Materials | Monel 400, Inconel 600, Hastalloy, 347 Stainless, and more! |

HART O-Ring Union Features:

- Turbulence Free: All unions provide a turbulence-free fit across the seats

- O-Ring Isolation: The O-Ring seal is strategically located in the thread

piece face eliminating O-Ring media contact and added protection against abrasives and erosion. A variety of O-Rings for any application are available. - Precision Machined Components: All unions are precision machined to provide high quality and fail-safe leak proof reliability.

- Interchangeable End Connections: HART’s male threaded connections feature interchangeable configurations with other threaded or welded connections, reducing the need for nipples or additional fittings.

- Material Versatility: Unions can be provided in all standard metals or combinations of metals. This includes 304 Stainless, 316 Stainless, A105 Carbon Steel, Brass, Monel 400, Hastelloy, and Titanium.

- Excellent Vibration Resistance: Seals will not loosen, even under extreme pressure and pressure surges.

- No Maintenance: Once the initial seal is made, no further tightening is required.

Many types of applications use high-temperature and steam unions to connect piping systems in harsh environments. For example, the pulp and paper industry may use them for hot oil rotary systems.

Other possible industries and applications that use these fittings include:

HART Industrial Unions’ Capabilities

High-temperature / steam unions help improve efficiency and dependability in environments with extreme temperatures, pressure levels, and other types of potentially damaging conditions. To provide sufficient protection, you need to find the right fittings for pipelines.

HART Industrial Unions provides custom high-temp / steam unions for nearly any application. Our unions feature superior construction that maximizes their longevity and reliability. We also work to meet national standards with each spiral wound gasket, including ASME B16.20 and MSS-SP-83. Our standard products include a graphite spiral wound gasket fitting, which is resistant to temperatures of up to 850° F (450° C) for superheated steam and hydrocarbon services. However, we offer options for higher temperatures, including solutions engineered for temperatures of 1,400° F (760° C) and higher. These include fittings for energy and turbine applications.

Our standard high-temperature / steam unions feature 316 stainless steel composition with a flexible graphite filler. Meanwhile, our optional products consist of 316 stainless steel and silicate filler. Additionally, we offer a selection of custom materials, including Inconel 600, Monel 400, 347 stainless steel, hastelloy, and more.

Other benefits of our high-temperature and steam unions include improved abrasion and erosion resistance due to the strategic thread-piece-face placement of the seal, excellent vibration resistance with consistently tight Sure Seal O-ring unions, material versatility, precision-machined parts, and end connections that are interchangeable.

You will also find plenty of other top-quality union designs in our extensive selection. These include male and female unions, buttweld unions, socketweld unions, orifice unions, hammer lug unions, copper sweat tube unions, and dielectric insulated unions.

To learn more about our Engineering and Manufacturing Capabilities, visit our Capabilities.

For additional product information and to get started on finding the right solution for your application, contact us today.