Fail Safe Leakproof Reliability

At any pressure, HART o-rings actually strengthen the seal rather than loosen it.

STANDARD O-RINGS

V Viton® Fluorocarbon A (FKM-A)

E Ethylene Propylene (EPDM)

ES High-Temp Steam EPDM [up to 550*F max] (EPDM E0962)

T Teflon® Tetrafluoroethylene (PTFE)

B Nitrile / Buna N (NBR)

SPECIALTY O-RINGS / SEALS

N Neoprene® Polycloroprene (CR)

K Kalrez® 4079 Perfluoroelastomer (FFKM)

HN Hydrogenated Nitrile (HNBR)

EP NSF-61 Approved EPDM (Ethylene Propylene)

G Metallic Graphite Spiral Wound Seal

I No o-ring (Integral Seat “Ball to Cone”)

Teflon®, Viton®, Kalrez® are Registered Trademarks from DuPont

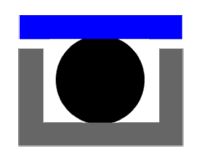

Static

The o-ring is fitted into a machined groove between the two halves of the union. When the halves are drawn together the o-ring compresses to an ovalized cross-section, forming a positive, resilient seal which serves to block the fluid, thus sealing even at low or no pressure.

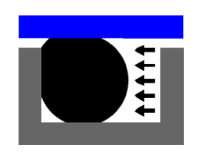

Under Load

As pressure is increased the o-ring is forced to flow and is “squeezed” into the downstream side causing the o-ring to conform to the shape of the end, blocking the groove gap. The more the system pressure increases, the more effective the seal.

Straight-Away Breakout

The flat-faced construction allows for slipping the component in and out without disturbing the surrounding tube or pipe sections. Pipe alignment is much easier with HART Unions since it is unnecessary to spring the line during make-up or disassembly.

Specialty Orders

Specialty o-rings also available. Inquire within.