Dielectric insulated unions provide dielectric insulation between two dissimilar metals, which prevents galvanic corrosion. Some examples of dissimilar metals are:

- Galvanized iron and copper

- Carbon steel and stainless steel

- Carbon steel and copper

- Stainless steel and copper

Should these metals meet in direct contact, corrosion can occur over time. Dielectric insulated fittings ultimately keep dissimilar metals from corroding each other, which is a potential risk for many types of metal pipelines.

In many connections, any acid present in water could cause an electrolytic response between different metals. This could result in the electrons from one metal feeding into another in an electric current. One metal loses molecules and deteriorates, and the other ends up collecting more and more of this by-product the longer the pipes are in use. This is the process of galvanic corrosion, which a dielectric insulated union prevents.

Dielectric Insulated Series Class 3000 and 6000 Unions

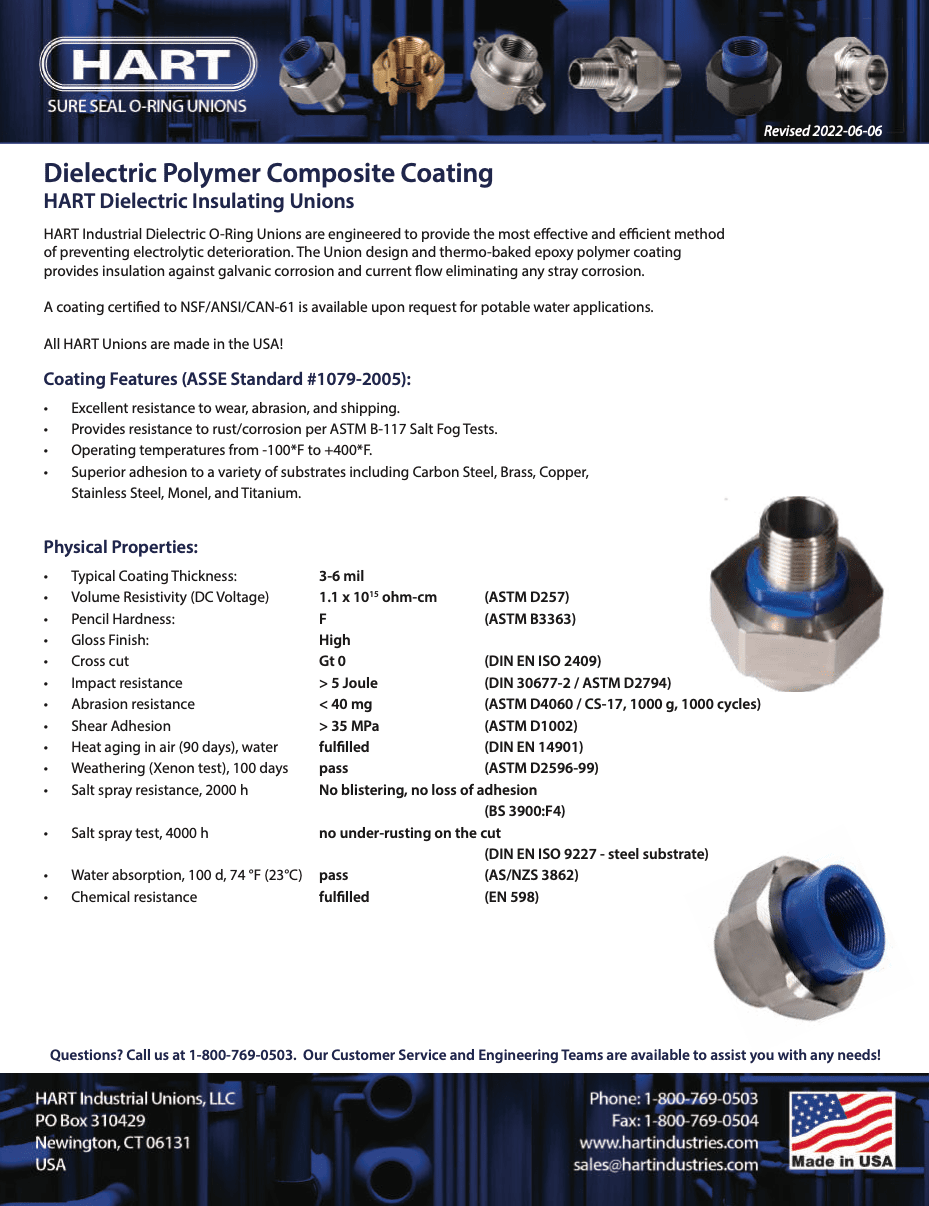

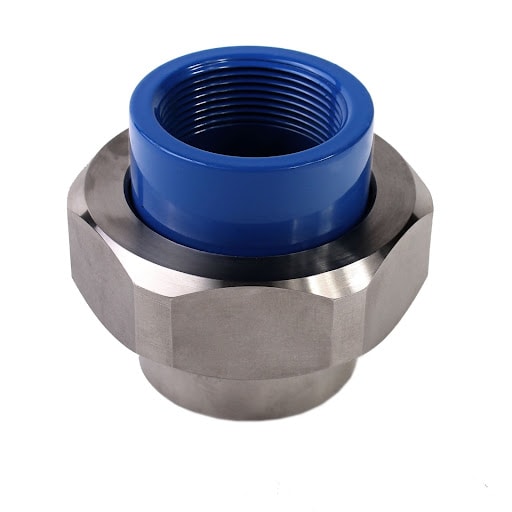

HART Industrial Dielectric Insulated O-Ring Unions are engineered to provide the most effective and efficient method of preventing electrolytic deterioration. The Union design provides insulation against galvanic corrosion and also breaks current flow eliminating any stray corrosion. The thermo-baked epoxy polymer coating provides >600 volts/mil dielectric resistance.

HART Industrial Unions revolutionized the dielectric pipe union by utilizing an epoxy-composite powder coating that is baked onto the tailpiece of the union. The tailpiece must be a threaded style connection, so as not to damage the coating during installation. However, the thread piece of the union can be any style of connection, welded or threaded. This allows for various configurations in dissimilar metal piping applications that require dielectric insulation.

HART O-Ring Union Features:

- Turbulence Free: All unions provide a turbulence-free fit across the seats

- O-Ring Isolation: The O-Ring seal is strategically located in the thread

piece face eliminating O-Ring media contact and added protection against abrasives and erosion. A variety of O-Rings for any application are available. - Precision Machined Components: All unions are precision machined to provide high quality and fail-safe leak proof reliability.

- Interchangeable End Connections: HART’s male threaded connections feature interchangeable configurations with other threaded or welded connections, reducing the need for nipples or additional fittings.

- Material Versatility: Unions can be provided in all standard metals or combinations of metals. This includes 304 Stainless, 316 Stainless, A105 Carbon Steel, Brass, Monel 400, Hastelloy, and Titanium.

- Excellent Vibration Resistance: Seals will not loosen, even under extreme pressure and pressure surges.

- No Maintenance: Once the initial seal is made, no further tightening is required.

Dielectric Insulated Series Class 3000 and 6000 Unions

-

Specifications

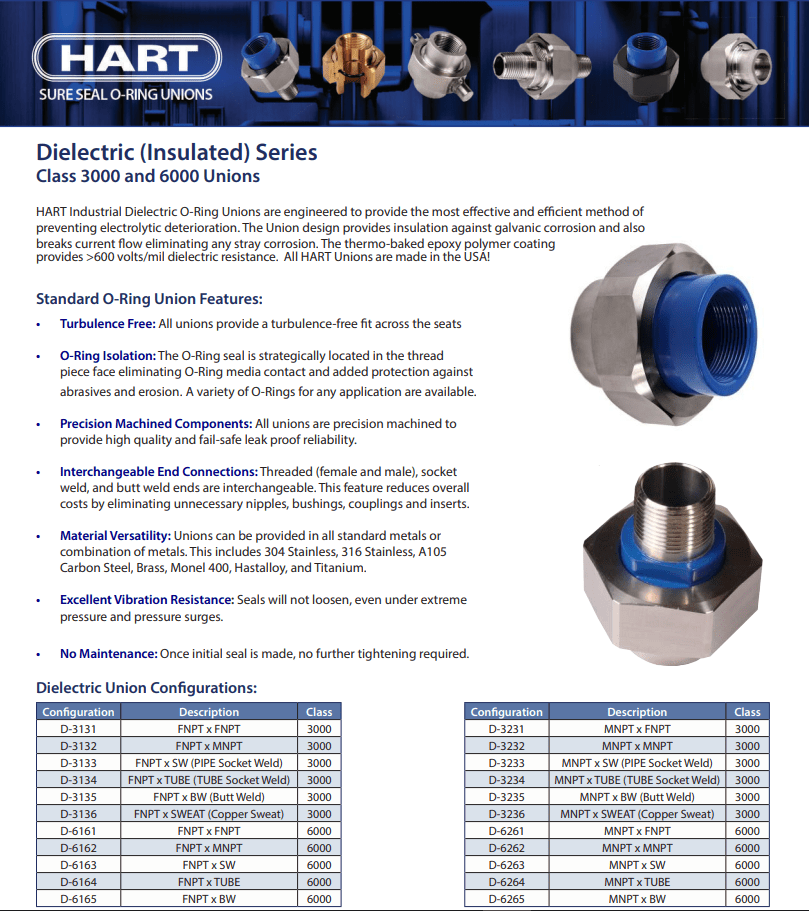

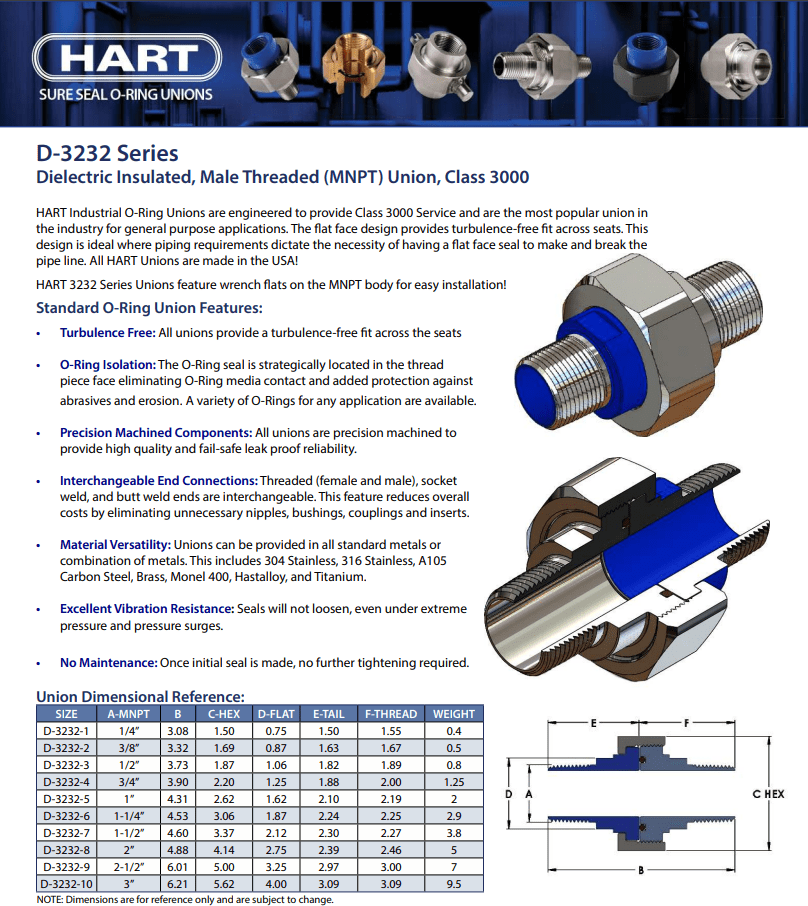

Configuration Description Class D-3131 FNPT * FNPT 3000 D-3132 FNPT * MNPT 3000 D-3133 FNPT * SW (Pipe Socket Weld) 3000 D-3134 FNPT * TUBE (Tube Socket Weld) 3000 D-3135 FNPT * BW (Butt Weld) 3000 D-3136 FNPT * SWEAT (Copper Sweat) 3000 D-6161 FNPT * FNPT 6000 D-6162 FNPT * MNPT 6000 D-6163 FNPT * SW 6000 D-6164 FNPT * TUBE 6000 D-6165 FNPT * BW 6000 Configuration Description Class D-3231 MNPT * FNPT 3000 D-3232 MNPT * MNPT 3000 D-3233 MNPT * SW (Pipe Socket Weld) 3000 D-3234 MNPT * TUBE (Tube Socket Weld) 3000 D-3235 MNPT * BW (Butt Weld) 3000 D-3236 MNPT * SWEAT (Copper Sweat) 3000 D-6261 MNPT * FNPT 6000 D-6262 MNPT * MNPT 6000 D-6263 MNPT * SW 6000 D-6264 MNPT * TUBE 6000 D-6265 MNPT * BW 6000 - 3D Animations

-

Datasheets

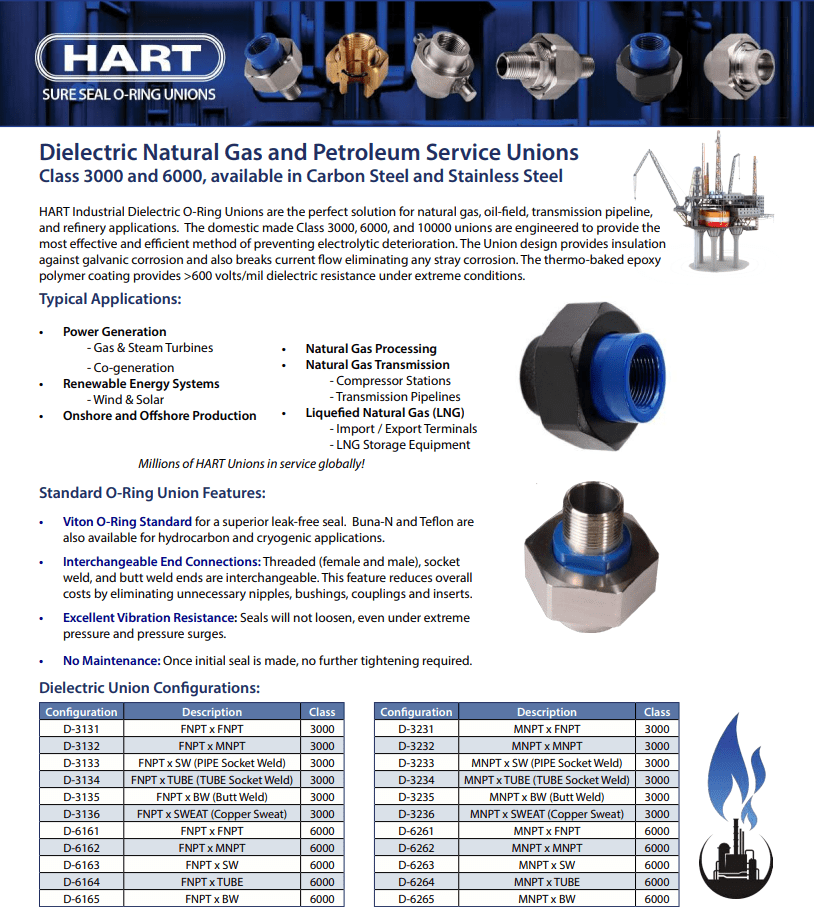

Many types of residential and commercial applications require dielectric insulated unions to prevent corrosion from taking place as a result of galvanic current. Subsequently, these unions help safeguard against deterioration. Ideal for plumbing applications, if a piping system features any connections containing various metals, dielectric unions will maintain their integrity. These unions also play a part in power generation, particularly with gas and steam turbines, and natural gas processing. Although dielectric insulated unions work with a wide range of applications, some systems may use brass fittings and nipples as alternatives when there are water quality concerns for rust buildup.

HART Industrial Unions’ Capabilities

At HART Industrial Unions, we offer a selection of dielectric insulated unions that can effectively prevent electrolytic deterioration. Our union design combined with a thermo-baked epoxy polymer coating provide sufficient insulation to protect against galvanic and stray corrosion.

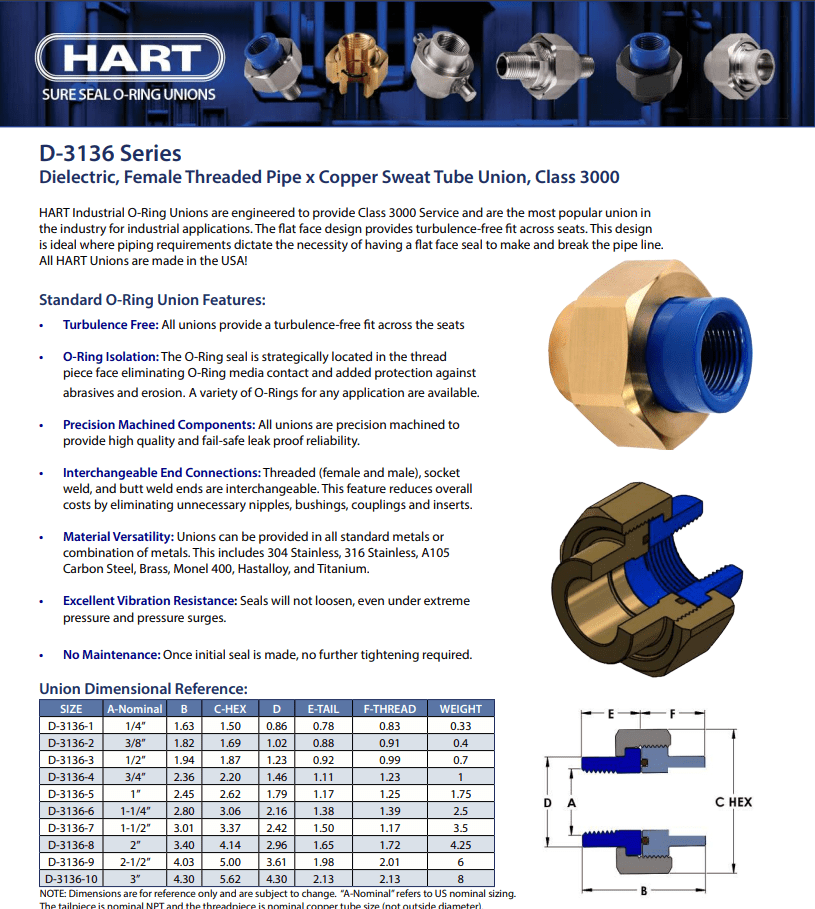

We produce custom unions of numerous material compositions, including carbon steel. Our available connection types on the thread piece side include welded, threaded, and sweat, among others. We also manufacture unions to help transition between piping of different sizes. As the leading domestic supplier of Sure Seal O-ring unions, we engineer our components to resist abrasion and erosion, and provide Class 3000 and 6000 services, with Class 10000 dielectric unions. These unions also have the advantage of a turbulence-free fit across the seats, which is ideal for piping systems requiring flat-face seals.

Regardless of what you require for your pipelines, HART Industrial Unions has the right products available. In addition to dielectric insulated unions, we provide other fitting designs, including female and male threaded unions, socketweld unions, buttweld unions, orifice unions, and more. Our reliable unions are all made in the USA and designed to meet your unique specifications.

To learn more about our Engineering and Manufacturing Capabilities, visit our Capabilities.

If you would like additional information about our precision-machined components and capabilities, contact us today.

HART Dielectric Insulating Unions

HART Dielectric Insulating Unions